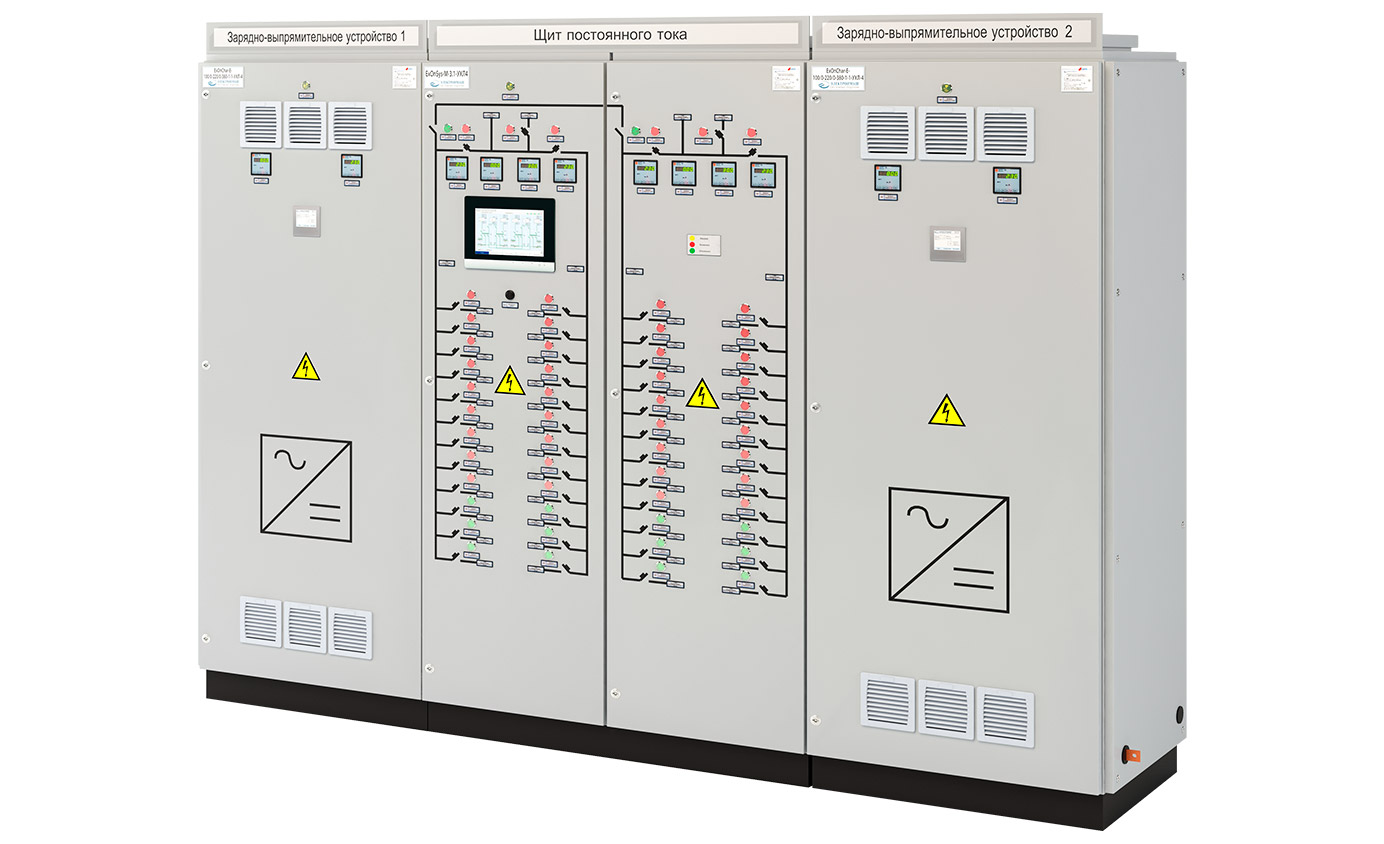

Monitoring and control systems intergated into DC Systems

The monitoring and control system integrated into ExOnSys line is used for diagnosing and managing DC systems , featuring an advanced analytical tool that enhances the reliability of power supply for critical consumers and the functioning of power supply systems.

>62

products manufactured and delivered to Customer sites

Main advantages

Modifications of Monitoring and control systems intergated into DC Systems

-01

Monitoring and control systems intergated into DC Systems

Monitoring system for predictive maintenance, diagnostics and management of all DC system equipment and components, including battery and DC Charger

-02

Monitoring and control systems intergated into DC Panels

Monitoring system for predictive maintenance, diagnostics and management of all DC panel equipment and components housed in a single cabinet