Safe, eco-friendly, economical

and efficient production process

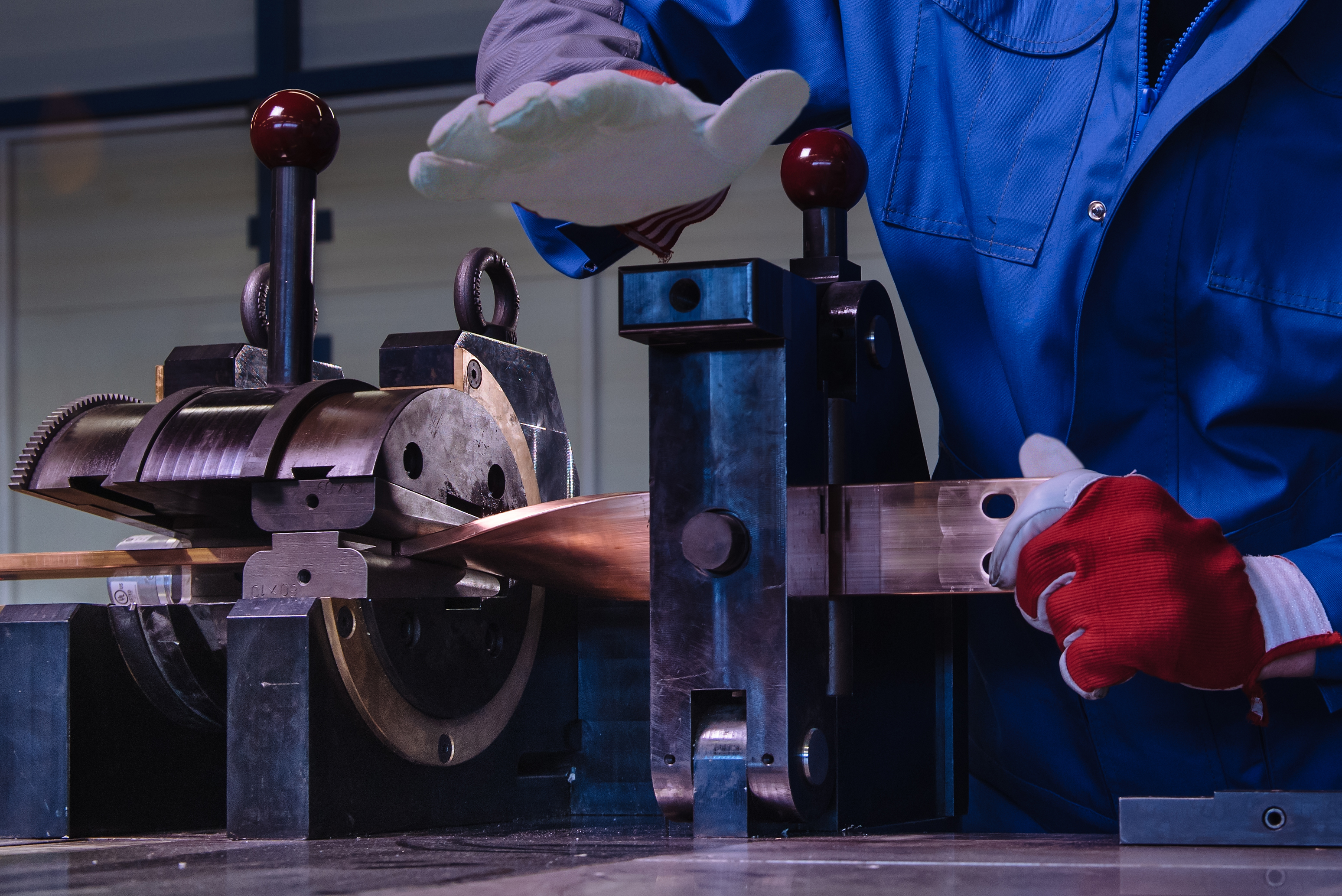

Equipment of own production

All processes from the development of design documentation to the shipment of finished products are fully automated and standardized

Conducting online monitoring of KPIs of production processes and constant work on their improvement

We use a single accounting system for registration and online monitoring of all production operations. Thanks to this, there is a continuous improvement in indicators.

KPI optimization of the number of documents and stages of the order

KPI reduction of equipment downtime

KPIs of efficiency and labor productivity

The implementation of product quality control is facilitated by full transparency of all processes.

We have implemented not only the principles of lean manufacturing, but also made the whole enterprise lean

Certification of production according to international standards

High level of motivation and qualifications of the company's employees

We pay great attention to the development and involvement of staff in the continuous improvement of the work performed and the services provided.,

Each employee of the company feels like a part of a single team, which leads to a desire to achieve a common goal and maximize work efficiency. Teamwork is based on making every effort for the success of the company, constant exchange of information, mutual training, and timely fulfillment of their direct duties by each employee.

Employees of any rank are confident in their ability to offer improvements. Each of the proposed improvements is considered and reviewed.

Constant updating of production facilities

The company has a program for updating and renovating the fleet, taking into account the promising developments of both manufacturers of the machine tool equipment itself and the needs of its own production of Electronmash for new products.

The annual budget of the enterprise is formed taking into account the formation of an equipment renewal fund.

The purpose of the program is to reduce the overall complexity of production, increase productivity and quality of products, and maintain production at a modern level. This allows our company to remain constantly competitive.

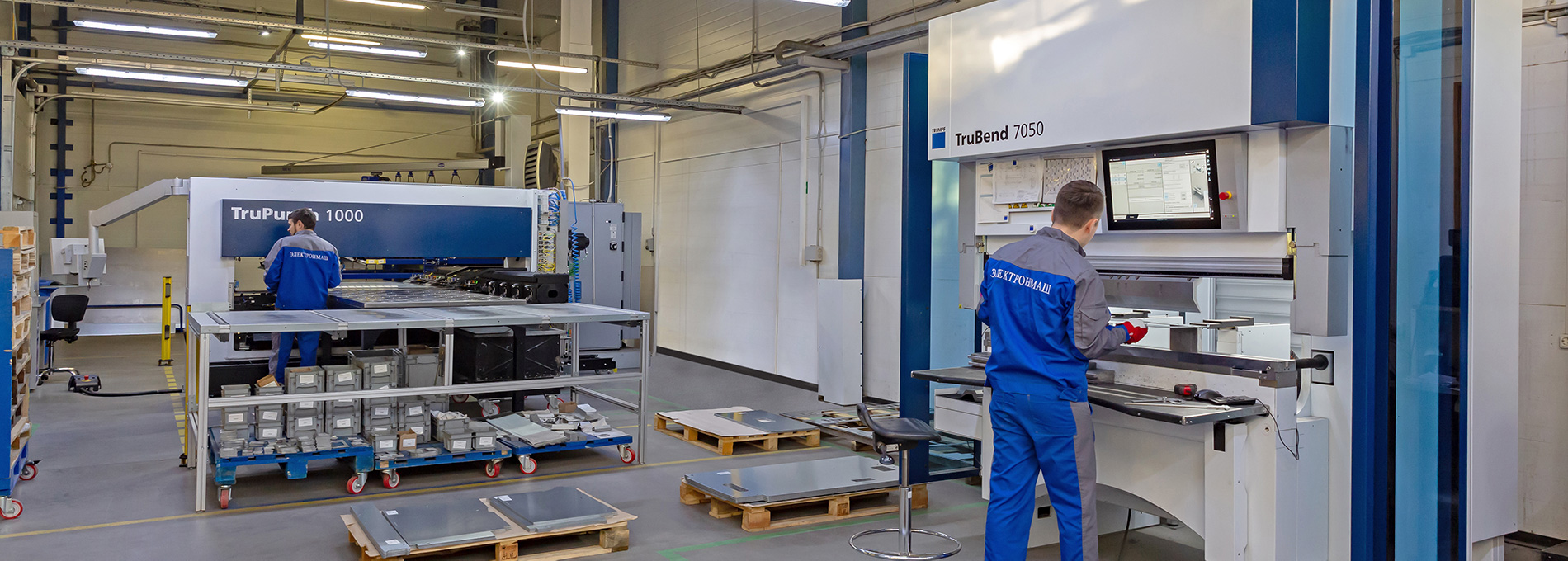

Modern machine park

Our machine park is specially selected to achieve

the highest level of safety, automation and high productivity. Only the machines of recognized

world industry leaders are used: Trumpf, Amada, and Shmaltz.

Electrical equipment for fossil fuels based energy sources and renewables

Product Catalog

Guarantee of stable quality and delivery time

Not only a supplier,

but a true partner who lives

and thinks solving customer problems

and thinks solving customer problems